News

- 2025/11/17

- CoboSafe CBSF – Force Measurement for Collaborative Robot Safety

-

CoboSafe CBSF – Force Measurement for Collaborative Robots CoboSafe CBSF

A force and pressure measurement system for safe human–robot collaboration.

Product Overview

CoboSafe by GTE Industrieelektronik GmbH (Germany) is a measurement system designed to verify forces and pressures occurring during human–robot collaboration. It enables objective evaluation of collision and pinch hazards in accordance with international safety standards.

With its modular design, the system can be configured according to the task, contact area, and robot type, allowing users to build an optimal measurement setup for each application.

Applicable Standards

- ISO/TS 15066

- EN ISO 10218-1 / 10218-2

- DGUV Guidelines

- RIA TR R15.806-2018 (ANSI)

Why Force Measurement Is Required

When introducing collaborative robots, human safety is the highest priority and a risk assessment is mandatory. In environments without physical safety fences, contact between humans and robots cannot be completely eliminated.

By measuring actual impact force and pressure under real operating conditions, CoboSafe provides quantitative evidence that forces remain within the allowable limits defined by safety standards. This improves reliability, compliance, and trust in collaborative robot applications.

Main Product Lineup

Model Description CBSF-Basic Handheld device with fixed spring constant (75 N/mm) for measuring impact force on body parts excluding the head. CBSF-XS Compact force measurement device optimized for grippers and narrow spaces, with LED status indication. CBSF Modular system with nine selectable spring constants (10–150 N/mm) for different body regions.

Pressure Measurement Options

Optional pressure measurement systems such as CoboSafe-Scan (pressure-sensitive film and scanner) and the electronic CoboSafe-Tek system allow detailed analysis of pressure distribution, peak pressure, and time-dependent behavior.

Measurement results can be analyzed using the Windows-based CoboSafe-Vision software, which supports graphical visualization, automatic report generation, and CSV data export.

Typical Applications

- Risk assessment during introduction of collaborative robots

- Periodic safety inspections under real operating conditions

- Gripper force evaluation in human–robot collaboration (HRC)

- R&D and safety validation by system integrators and research institutions

- 2025/11/05

- TES Sharp Edge Tester – Designed to prevent injuries caused by sharp metal edges

-

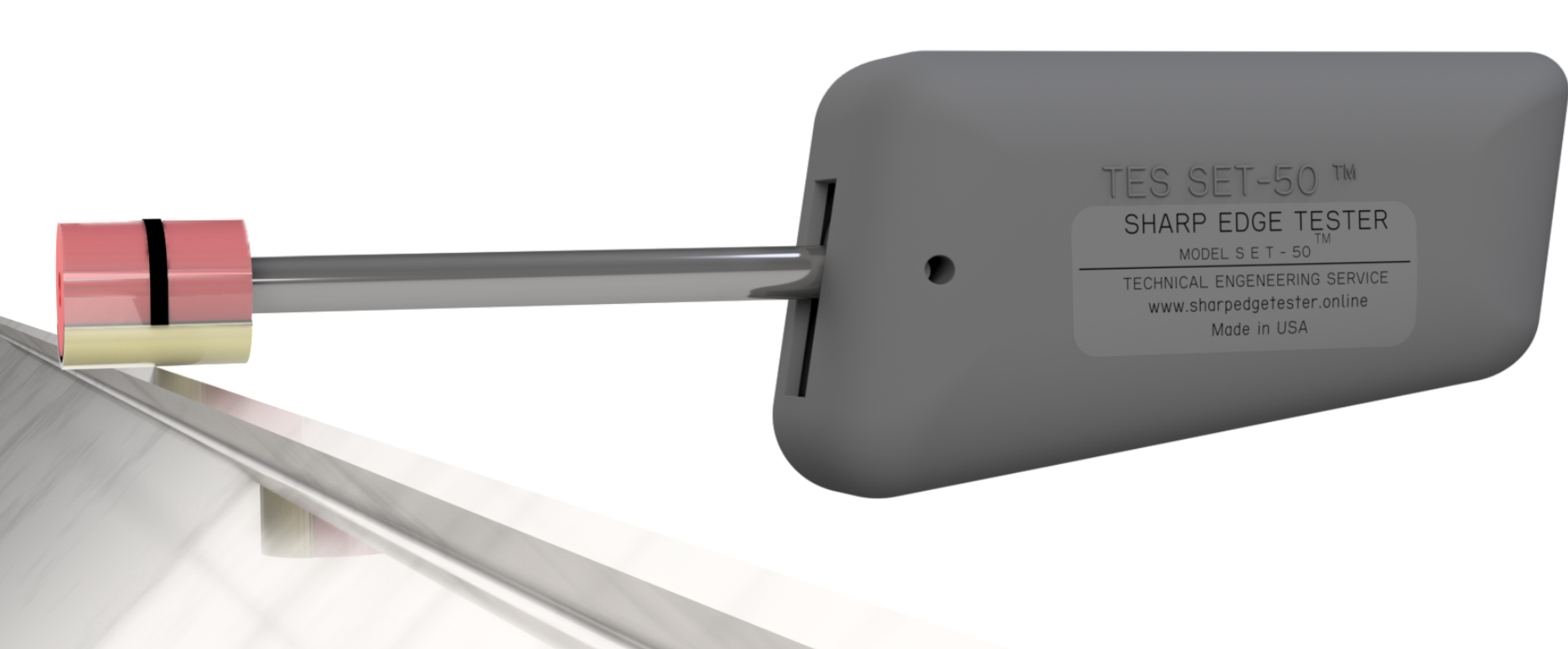

Sharp Edge Tester – TES Sharp Edge Tester – TES

A simple tool for verifying product safety and quality.

Product Overview

The Sharp Edge Tester is a globally recognized testing instrument that complies with UL1439 standards, providing an objective assessment of sharp-edge safety. A TC-3 tape kit simulates a human fingertip and is used to evaluate the hazard potential of burrs or sharp areas.

UL1439 Standard

UL1439 is a U.S. safety standard for evaluating the risk of injury caused by sharp edges on products that may come into contact with users. It applies to electrical and electronic equipment, home appliances, office devices, and more.

Test Method

- TC-3 tape (3-layer) is pressed against the edge with 6.7 N force

- Moved 50 mm back and forth (total 100 mm)

- Pass: Outer two layers remain intact

- Fail: Either outer layer is cut

Main Specifications (SET-50)

Parameter Specification Tension 6.7 N ± 0.02 N Test Distance 101.6 mm Applicable Standard UL1439 Options TC-3 tape kit, calibration weight Applications Electronic devices, toys, household products

- 2025/05/30

- New Product: Locking Stage – Compact Manual Stage with Patented Locking Mechanism

-

Locking Stage – Yanagisawa Locking × Easy Positioning × No Clamp

The Most Practical Manual Stage for Efficient Setup

Common Setup Challenges

- Having trouble setting up jigs?

- Need to adjust sensor or camera positions repeatedly?

- Looking for a space-saving manual stage with no clamp mechanism?

These problems can be solved with the new Locking Stage from Yanagisawa.

This stage allows for easy positioning and secure fixing using just one wrench.

No clamps. No locking levers. Just simple and fast setup.Key Features

- Tool-based one-step locking (position + hold)

- No clamp needed — saves space and simplifies design

- Ideal for cylindrical or round workpieces (stable V-base support)

- Perfect for manual adjustment of jigs, sensors, and inspection devices

Business Introduction

Specializing in trade of precision measuring instruments.

Abundant inventory and timely delivery.

Abundant overseas business experience and know-how in export trnsactions.

Contact

For consultation and inquiries,

please contact us using the e-mail form below or by phone.